(4 ratings)

(4 ratings)

ZF has unveiled the electrified automated manual gearbox technology that permits the hybridization of compact and small cars. This creative approach operates on front-transverse vehicles and unites an AMT option and electric axle drive system (eVD) in a single system.

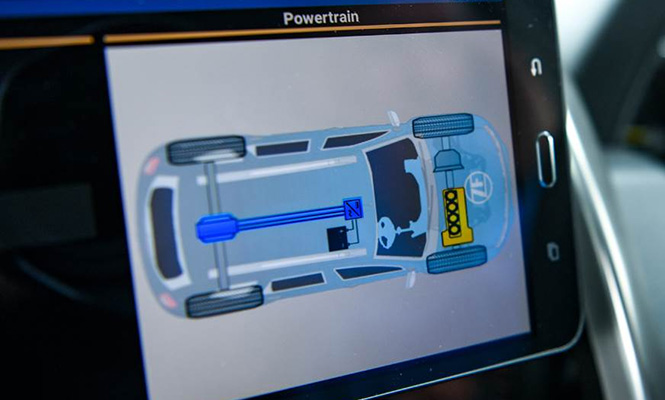

The electric rear axle and transmission actuator work together in relation to the intelligent interaction. This consequently shows that the eAMT concept is not continuing the tractive force interruption. An electric motor fills the gap between the AMT choice and interactive design. Furthermore, the hybrid working of electric drive and recovery and force, eAMT also runs on an electric all-wheel drive system. ZF software controls the coordination and networking of the internal combustion motor, automated transmission converter, and an electric motor.

ZF has mentioned an electric rear axle enhances automated converter to premium level, reducing tractive force interruption.

With the small to compact vehicles occupying hybridization along with front-wheel drive, have confronted with the price increase and require extra cost, efforts and limited installation option. Norman Schmidt-Winkel, functional developer of electric drives, ZF said, “With eAMT, ZF has developed a fully-fledged plug-in hybrid drive for front-transverse vehicles.”

Read Also: Maruti Vitara Brezza Recorded Fastest 3 Lakh Sales

“This increases flexibility for vehicle manufacturers. They can use existing platforms to implement conventional drives or plug-in hybrids. The ZF concept integrates an automated manual transmission and an electric axle drive system on the rear axle into one unit. In some vehicle classes, automatic transmissions are out of the question for reasons of weight, space or cost.”

“In this scenario, the automation of manual transmissions is a great way to significantly increase comfort and efficiency for drivers, as they don’t need to actuate the clutch or change gears.”

Consequently, the electric drive with intelligent drive management, performance, and comfort of the eAMT are approximately working perfectly in relation to the costly dual-clutch transmissions. With the AMT disengagement for a new gear engagement, the tractive force interruption occurs. This is basic for automated manual transmissions considering its design. The Traction Torque Support feature enables the new eAMT to compensate for the short stoppage in accelerative force. A rear axle electric drive fills up the gap with a timely insertion of torque.

Check This Full News: New Updated Honda Jazz To Introduce In India Soon

Schmidt-Winkel. Mentioned, “The driver is absolutely unaware of the complex system sequences and control processes running in the background.“ He further said, “When accelerating, only the benefits of completely jerk-free, powerful acceleration can be felt. Previously, these benefits would only be available in much more expensive hybrid vehicles with more complex transmissions. We also utilized the eAMT system´s potential for other features that increase efficiency and driving safety.”

The electric rear axle drive activates automatically with additional thrust requirement and supports gear changes. Further, ZF’s electric motor has the power to run the SUV under the electric power conditions alone. The SUV runs along with zero local emissions and all-electric modes. The eAMT working mode is only appropriate for creep mode during a traffic jam, parking, general manoeuvring and creep mode.

Contrary, eAMT as well activates coasting such as saves energy when sliding with the combustion engine drive system disengagement. The feature works perfectly with the asynchronous machine (ASM) attached at the rear. The plug-in hybrid option also comes with the known features like recuperation and automatic engine stop.